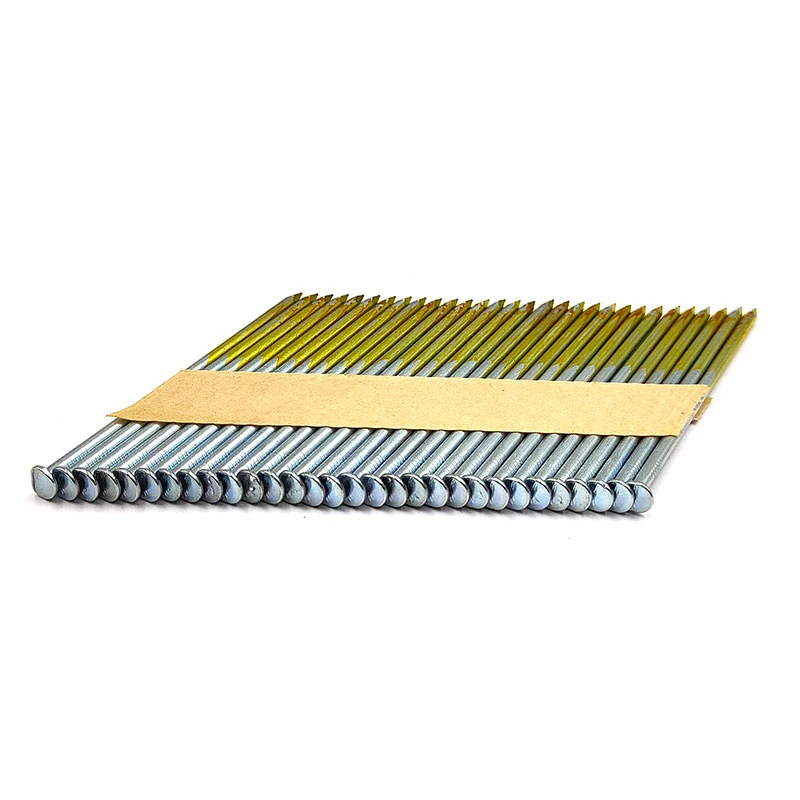

Galvanized framing nails are typically made from steel, which is a common material used for fasteners in construction applications. These nails are coated with a layer of zinc through a process called galvanization. The steel used for galvanized framing nails is typically low carbon or medium carbon steel, chosen for its strength, durability, and suitability for use in structural framing.

Low carbon steel is preferred for framing nails because it offers good weldability and formability, making it easy to manufacture into nails with the required shape and dimensions. Medium carbon steel may also be used for framing nails, especially in applications where higher tensile strength and hardness are desired.

The galvanization process involves immersing the steel nails in a bath of molten zinc or applying a zinc coating through electroplating or hot-dipping methods. This zinc coating provides a protective barrier against corrosion, extending the lifespan of the nails and protecting them from rust and degradation in outdoor or humid environments.

In addition to steel, some manufacturers may use other materials or alloys for specialty framing nails, such as stainless steel or aluminum. Stainless steel framing nails offer excellent corrosion resistance and are often used in coastal or marine environments where saltwater exposure is a concern. Aluminum framing nails are lightweight and resistant to rust, but they may not have the same strength and holding power as steel nails.