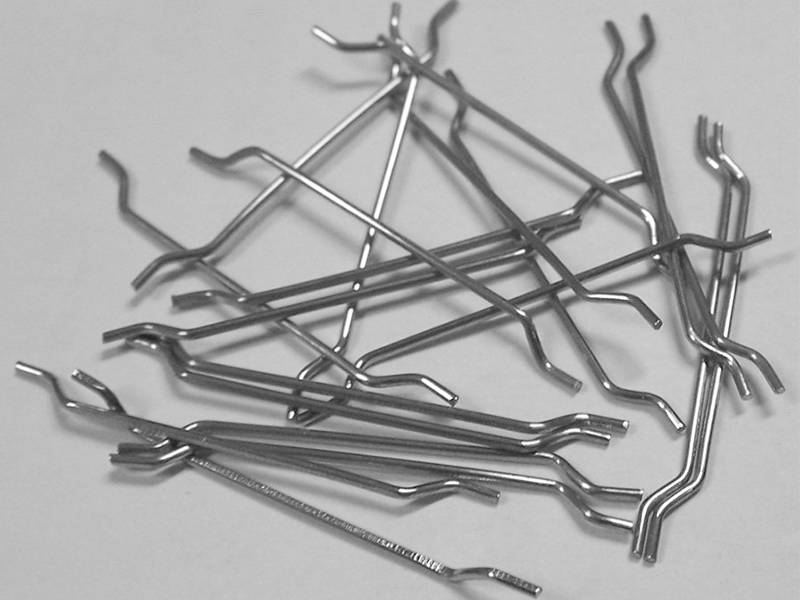

Hooked end steel fiber is a popular type of reinforcement used in concrete to improve its strength and durability. These fibers are made from high-quality steel and come with a unique hook shape at one end, which helps to anchor them securely into the concrete matrix. In this article, we will explore the benefits of using hooked end steel fiber, its applications, and how it can improve the performance of your concrete structures.