When it comes to flow control in pipelines, two commonly used valves are the globe valve and the gate valve. In this article, we will compare and contrast these two types of valves, highlighting their design, functionality, and applications. By understanding the differences between globe valves and gate valves, you can make an informed decision when selecting the appropriate valve for your specific needs.

Globe Valve: Versatile Flow Control Solution

Globe valves are versatile valves that offer precise flow control in various applications. In this section, we will explore the key features and advantages of globe valves, shedding light on their suitability for different industries and systems.

Design and Operation of Globe Valves

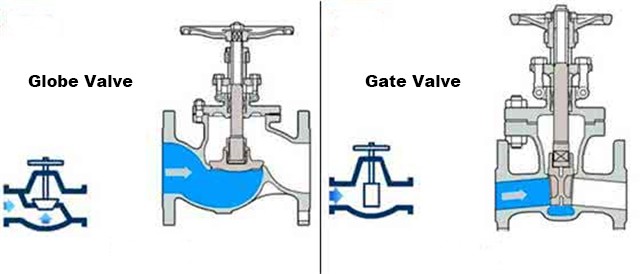

Globe valves feature a spherical body with an internal baffle and a movable disk or plug for flow regulation. They operate by raising or lowering the disk to control the flow of fluid. The unique design of globe valves allows for linear and accurate flow control, making them ideal for applications that require throttling or regulating the flow rate.

Applications of Globe Valves

Globe valves find extensive use in industries such as oil and gas, power generation, chemical processing, and water treatment. They are commonly employed in systems that require precise control of flow, such as cooling water circuits, steam lines, and hydraulic systems. The ability to finely tune flow rates makes globe valves suitable for applications where maintaining specific process parameters is critical.

Gate Valve: Efficient On/Off Flow Control

Gate valves are widely used for their efficient on/off flow control capabilities. In this section, we will explore the distinctive features and benefits of gate valves, highlighting their suitability for different industrial applications.

Design and Operation of Gate Valves

Gate valves feature a flat or wedge-shaped gate that slides perpendicular to the flow direction to control the flow of fluid. When fully open, gate valves offer minimal obstruction to flow, resulting in low-pressure drop. Their simple and robust design allows for quick and reliable shut-off, making them ideal for applications where full flow or no flow is required.

Applications of Gate Valves

Gate valves are commonly utilized in industries such as oil and gas, petrochemical, water distribution, and wastewater treatment. They are commonly found in systems that require infrequent operation or isolation, such as main pipelines, fire protection systems, and storage tanks. Gate valves excel in applications where a tight seal and reliable shut-off are essential.

Globe Valve vs. Gate Valve: Key Differences

In this section, we will compare the globe valve and the gate valve, highlighting their key differences in terms of design, functionality, and application suitability.

Design and Flow Control

Globe valves offer precise flow control and throttling capabilities, making them suitable for applications that require fine adjustments in flow rate. On the other hand, gate valves provide efficient on/off flow control, allowing for unobstructed flow when fully open and tight shut-off when closed.

Pressure Drop and Fluid Flow

Globe valves typically have a higher pressure drop compared to gate valves due to their design with a baffle and multiple directional changes. Gate valves, with their straight-through flow path, offer minimal pressure drop, making them more suitable for applications where low flow resistance is critical.

Application Suitability

Globe valves are commonly used in systems that require precise flow control and regulation, whereas gate valves are favored for applications that require infrequent operation, full flow or no flow, and tight shut-off.

Conclusion:

In summary, both globe valves and gate valves serve distinct purposes in flow control applications. Globe valves excel in providing precise flow control and throttling capabilities, making them suitable for applications that require accurate regulation. Gate valves, on the other hand, offer efficient on/off flow control and are commonly used in systems that require infrequent operation and tight shut-off. By understanding the differences between these valves, you can select the appropriate valve based on your specific requirements, ensuring optimal performance and reliability in your fluid control systems.