Grasp the critical role that 2 inch check valves play in ensuring the smooth operation of various industrial processes. Learn about their features, benefits, and applications, and how they can help prevent costly downtime and improve efficiency.

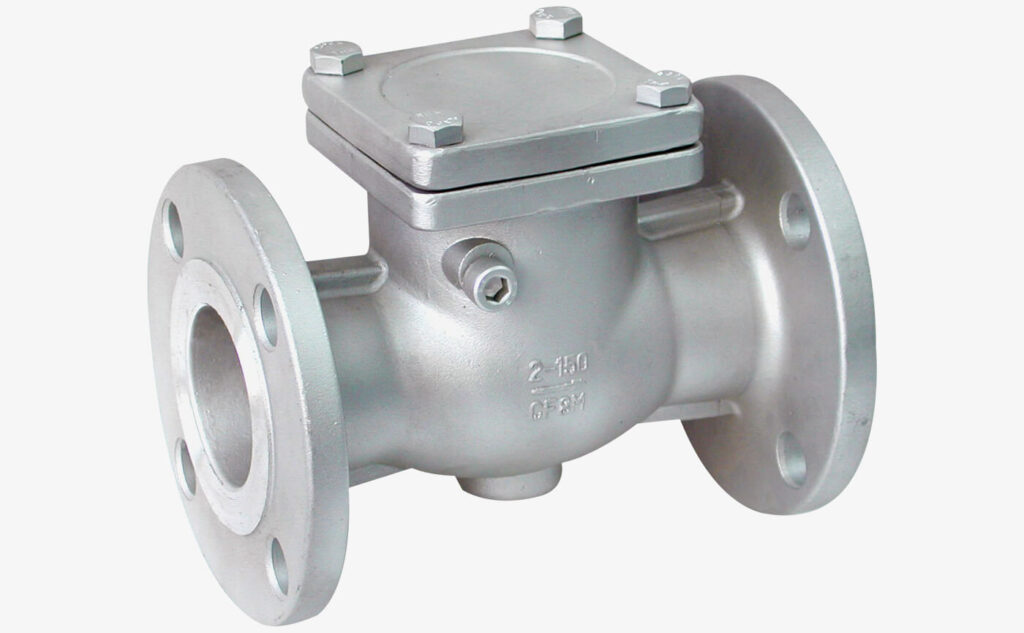

Introduction to 2 Inch Check Valves

2 inch check valves are an essential component in many industrial processes, playing a critical role in preventing backflow and ensuring the smooth operation of equipment. These valves are designed to allow fluid to flow in one direction while preventing it from flowing back in the opposite direction. In this article, we will explore the features, benefits, and applications of 2 inch check valves, and how they can help improve efficiency and prevent costly downtime.

Features of 2 Inch Check Valves

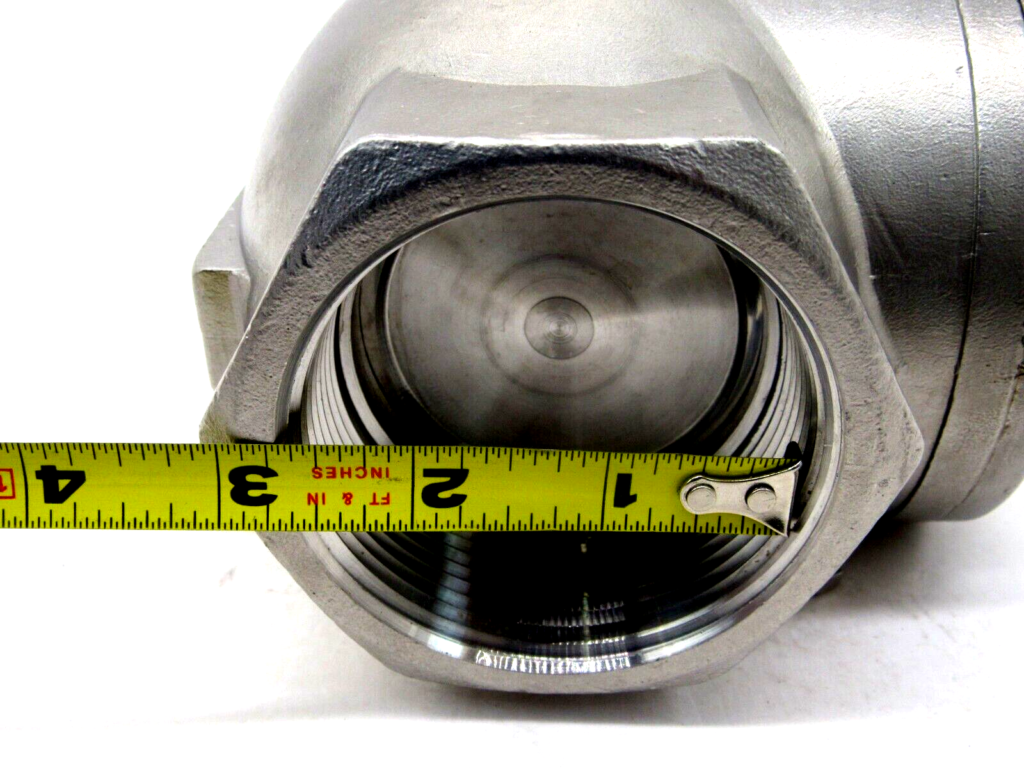

2 inch check valves are available in various configurations and materials to suit different industrial applications. They typically have a compact design, making them easy to install and maintain. These valves are also designed to handle high-pressure and high-temperature applications, making them suitable for use in harsh environments. Some common features of 2 inch check valves include:

- Spring-loaded or pilot-operated designs

- Brass, stainless steel, or aluminum construction

- NPT or BSP threaded connections

- Precision-machined components for smooth operation

Benefits of 2 Inch Check Valves

The use of 2 inch check valves offers several benefits to industrial processes, including:

- Prevention of backflow: 2 inch check valves ensure that fluid flows in one direction, preventing backflow and contamination of the process fluid.

- Improved efficiency: By preventing backflow, 2 inch check valves help to maintain the desired flow rate and pressure, improving the overall efficiency of the process.

- Reduced downtime: The use of 2 inch check valves helps to prevent equipment damage and costly downtime caused by backflow and contamination.

- Increased safety: 2 inch check valves help to prevent accidents and injuries caused by backflow and equipment failure.

Applications of 2 Inch Check Valves

2 inch check valves are widely used in various industrial applications, including:

- Chemical processing: 2 inch check valves are used to prevent backflow and contamination of chemicals, acids, and other corrosive fluids.

- Oil and gas production: These valves are used to prevent backflow and contamination of oil and gas, as well as to regulate the flow of fluids in pipelines.

- Water treatment: 2 inch check valves are used to prevent backflow and contamination of water, as well as to regulate the flow of water in treatment plants.

- HVAC systems: These valves are used to prevent backflow and contamination of coolants and refrigerants in HVAC systems.

Conclusion:

In conclusion, 2 inch check valves play a critical role in ensuring the smooth operation of various industrial processes. Their compact design, high-pressure and high-temperature capabilities, and precision-machined components make them suitable for use in harsh environments. The use of 2 inch check valves helps to prevent backflow, improve efficiency, reduce downtime, and increase safety. By understanding the features, benefits, and applications of 2 inch check valves, industries can make informed decisions about their use and enjoy improved process performance and profitability.