Gate valves are crucial components in fluid control systems, offering precise control over the flow of liquids and gases. This article provides a comprehensive overview of gate valve function, highlighting its importance, working principle, and applications. Understanding the function of gate valves is essential for industries that rely on efficient and reliable fluid control.

The Importance of Gate Valve Function

Gate valves serve several critical functions in fluid control systems:

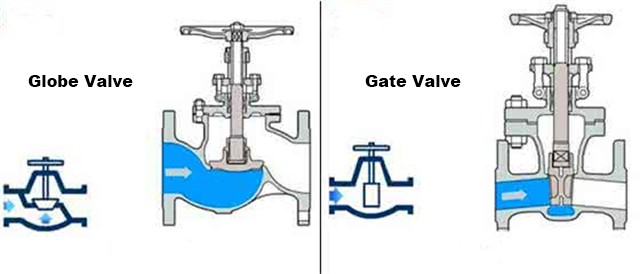

- Flow Regulation: Gate valves allow for precise regulation of fluid flow by providing a full-bore opening when fully open and complete shut-off when fully closed, ensuring efficient control over the system.

- Bi-Directional Service: Gate valves are designed to operate in both directions, allowing for bidirectional flow control, making them versatile for various piping configurations.

- Leak Tightness: When fully closed, gate valves provide a tight seal, preventing leakage and ensuring system integrity, especially in applications that require zero or minimal leakage.

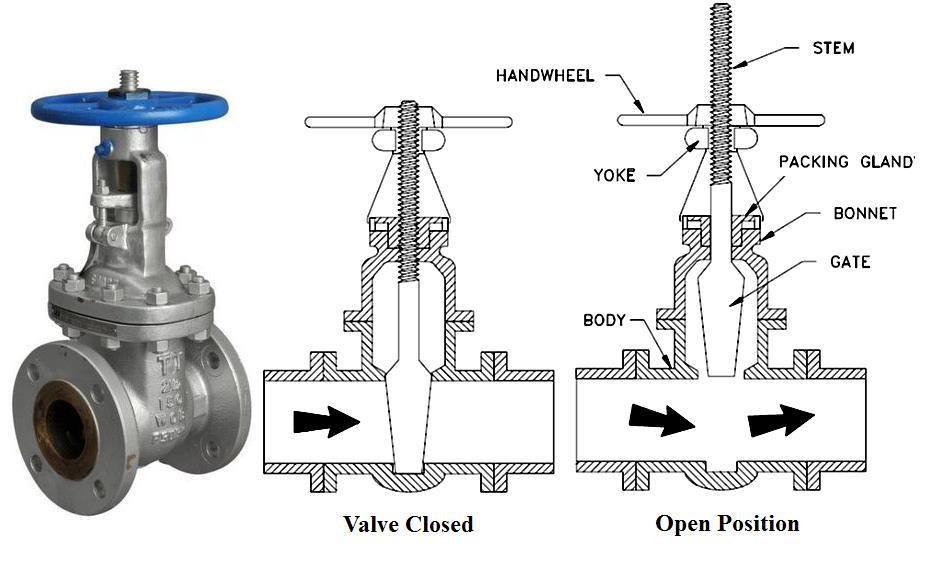

Working Principle of Gate Valves

Gate valves operate based on a straightforward principle:

- Open Position: When the gate valve is fully open, the gate is lifted entirely, allowing fluid to flow freely through the full-bore opening, minimizing pressure drop.

- Closed Position: When the gate valve is fully closed, the gate is lowered, forming a tight seal against the valve seat, preventing any flow through the system.

Applications of Gate Valve Function

Gate valves find extensive applications across various industries:

- Water Supply Systems: Gate valves are commonly used in water treatment plants, distribution networks, and reservoirs, providing reliable flow control for domestic and industrial water supply.

- Oil and Gas Industry: Gate valves play a crucial role in upstream, midstream, and downstream operations, regulating the flow of crude oil, natural gas, and refined products in pipelines and refineries.

- Power Generation: Gate valves are essential in power plants, controlling the flow of steam, condensate, and cooling water in boilers, turbines, and heat exchangers.

Installation and Maintenance of Gate Valves

Proper installation and maintenance practices are essential for the optimal performance of gate valves:

- Selection: Choose the appropriate gate valve based on the application requirements, considering factors such as pressure rating, temperature range, and material compatibility.

- Installation: Ensure proper alignment and support during installation to prevent stress on the valve body and ensure smooth operation. Follow manufacturer guidelines for torque specifications.

- Routine Maintenance: Regularly inspect gate valves for signs of wear, corrosion, or leakage. Lubricate moving parts as recommended by the manufacturer and promptly address any issues to maintain optimal performance.

Example of Gate Valve Function in Action

In a municipal water treatment plant, gate valves are installed along the distribution network to regulate water flow to different areas. By adjusting the gate valve position, operators can control the water supply to specific regions, ensuring efficient distribution and preventing water loss.

Conclusion

Gate valves play a vital role in fluid control systems, offering precise flow regulation, bidirectional service, and leak-tight operation. Their applications range from water supply systems to the oil and gas industry and power generation.

By understanding the function of gate valves and following proper installation and maintenance practices, industries can ensure efficient and reliable fluid control, contributing to the overall performance of their systems.