Gate valves are essential components in various industrial processes, and their proper operation is crucial for ensuring efficiency and safety. As a leading manufacturer of gate valves, TWT understands the importance of providing clear and concise instructions for their operation.

Introduction

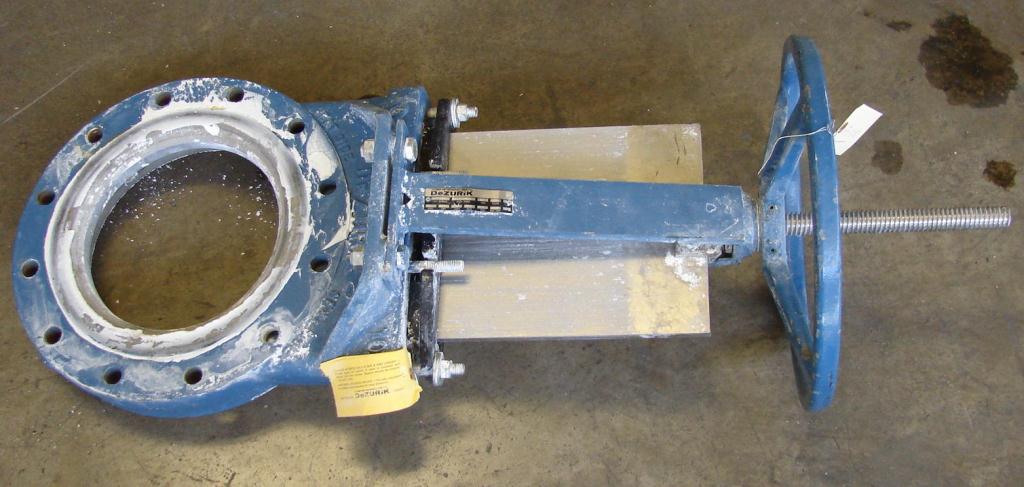

Gate valves are used to control the flow of fluids in various industries, including oil and gas, chemical processing, and water treatment. They are designed to open and close a passageway, allowing or blocking the flow of fluids. The proper Gate Valve Operation is critical for ensuring the safety and efficiency of the process.

H1: Types of Gate Valves

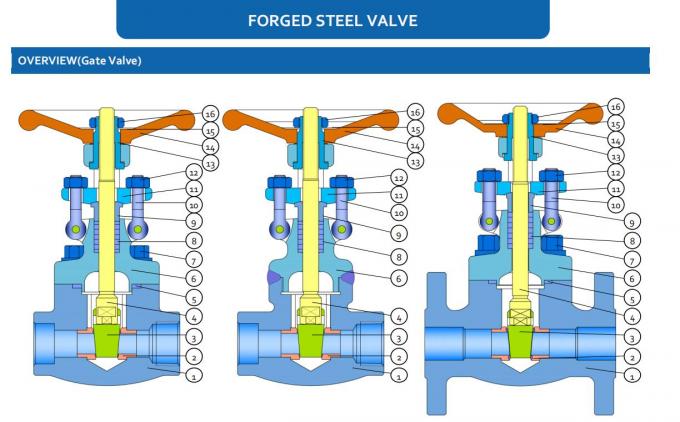

There are several types of gate valves, each designed for specific applications. The most common types are:

- Rising stem gate valve

- Non-rising stem gate valve

- Wedge gate valve

- Parallel slide gate valve

Each type of gate valve has its unique features and applications. Understanding the differences between them is essential for selecting the right valve for your process.

H2: Gate Valve Operation

The operation of a gate valve involves opening and closing the valve to control the flow of fluids. The valve is opened by rotating the handle or wheel in a clockwise direction, which raises the gate and allows the fluid to flow. The valve is closed by rotating the handle or wheel in a counterclockwise direction, which lowers the gate and blocks the flow of fluid.

The gate valve operation can be further explained by the following steps:

- Opening the valve:

- Rotate the handle or wheel clockwise to raise the gate.

- The gate rises until it reaches the fully open position.

- The fluid flows through the valve.

- Closing the valve:

- Rotate the handle or wheel counterclockwise to lower the gate.

- The gate descends until it reaches the fully closed position.

- The fluid flow is blocked.

H3: Factors Affecting Gate Valve Operation

Several factors can affect the operation of a gate valve, including:

- Pressure: The pressure of the fluid flowing through the valve can affect its operation. High pressure can make it difficult to open the valve, while low pressure can make it difficult to close.

- Temperature: The temperature of the fluid can also affect the operation of the valve. High temperatures can cause the valve to expand, making it difficult to close, while low temperatures can cause the valve to contract, making it difficult to open.

- Flow rate: The flow rate of the fluid can also impact the operation of the valve. High flow rates can cause the valve to vibrate, making it difficult to control, while low flow rates can cause the valve to stick, making it difficult to open or close.

Understanding these factors is essential for ensuring the proper operation of the gate valve.

Conclusion

In conclusion, the proper operation of a gate valve is crucial for ensuring the safety and efficiency of various industrial processes. TWT gate valves are designed to provide reliable performance and a long lifespan. By understanding the fundamentals of gate valve operation and following the guidelines provided in this article, users can ensure the optimal performance of their TWT gate valves.

FAQs

- What are the different types of gate valves?

- Rising stem gate valve

- Non-rising stem gate valve

- Wedge gate valve

- Parallel slide gate valve

- How do I open a gate valve?

- Rotate the handle or wheel clockwise to raise the gate.

- How do I close a gate valve?

- Rotate the handle or wheel counterclockwise to lower the gate.

- What factors can affect the operation of a gate valve?

- Pressure

- Temperature

- Flow rate

- How do I maintain my TWT gate valve?

- Regularly inspect the valve for wear and tear.

- Lubricate the moving parts regularly.

- Replace the valve seat and gasket as needed.