Lift check valves are an essential component in many industrial applications, including hydraulic systems, pumps, and machines. In this article, we will provide a comprehensive guide to lift check valves, including their definition, functions, types, and applications.

Definition of Lift Check Valve

A lift check valve is a type of valve that is designed to prevent the backflow of fluid in a system. It is typically installed in a vertical position, and its main function is to allow fluid to flow upward while preventing it from flowing downward. This ensures that the system remains pressurized and functional.

Functions of Lift Check Valve

Lift check valves perform several critical functions in a system, including:

Preventing backflow: Lift check valves prevent the backflow of fluid in a system, which can cause damage to the equipment and disrupt the operation.

Maintaining pressure: Lift check valves help maintain the pressure in a system by preventing the fluid from flowing back down. This ensures that the system remains pressurized and functional.

Preventing contamination: Lift check valves can prevent contamination of the fluid in a system by preventing the backflow of dirty or contaminated fluid.

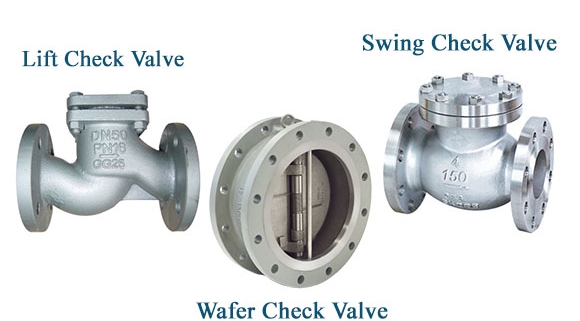

Types of Lift Check Valves

There are several types of lift check valves available, including:

Spring-loaded lift check valves: These valves use a spring to maintain the pressure in the system. When the pressure exceeds the spring’s force, the valve opens, allowing fluid to flow upward.

Pilot-operated lift check valves: These valves use a pilot valve to control the flow of fluid. When the pressure exceeds the pilot valve’s set point, the valve opens, allowing fluid to flow upward.

Diaphragm-type lift check valves: These valves use a flexible diaphragm to separate the upstream and downstream parts of the valve. When the pressure exceeds the diaphragm’s strength, the valve opens, allowing fluid to flow upward.

Applications of Lift Check Valves

Lift check valves have a wide range of applications in various industries, including:

Hydraulic systems: Lift check valves are used in hydraulic systems to prevent backflow and maintain pressure.

Pumps: Lift check valves are used in pumps to prevent backflow and maintain pressure.

Machines: Lift check valves are used in machines to prevent backflow and maintain pressure.

Aerospace: Lift check valves are used in aerospace applications to prevent backflow and maintain pressure.