Check valves are an essential component in many industrial applications, ensuring the proper flow of fluids and gases while preventing reverse flow and pressure buildup. In this article, we will delve into the definition, types, and applications of check valves, as well as their benefits and importance in various industries.

What is a Check Valve

Check Valve Definition and Types

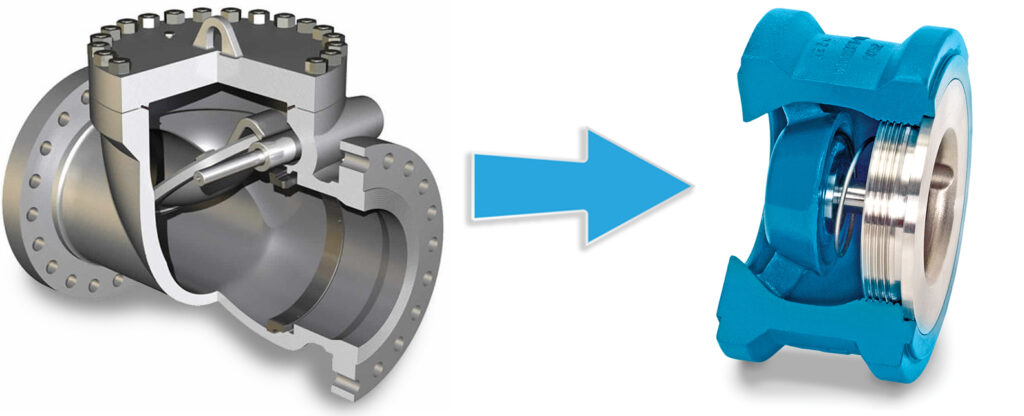

A check valve is a type of valve that allows fluid or gas to flow in one direction while preventing reverse flow. There are several types of check valves available, including:

- Swing check valve: This type of check valve uses a swinging disc to block reverse flow.

- Stop check valve: This type of check valve uses a poppet or stopper to block reverse flow.

- Diaphragm check valve: This type of check valve uses a diaphragm to block reverse flow.

- Ball check valve: This type of check valve uses a ball to block reverse flow.

Applications of Check Valves

Check Valve Applications in Various Industries

Check valves are used in a wide range of industries, including:

- Oil and gas: Check valves are used to prevent reverse flow in oil and gas pipelines, as well as in pumps and compressors.

- Chemical processing: Check valves are used to prevent reverse flow in chemical processing plants, as well as in reaction vessels and distillation columns.

- Power generation: Check valves are used to prevent reverse flow in power generation systems, such as in steam turbines and generators.

- Water treatment: Check valves are used to prevent reverse flow in water treatment plants, as well as in water distribution systems.

Benefits of Check Valves

Benefits of Check Valves

Check valves offer several benefits, including:

- Preventing reverse flow: Check valves to prevent reverse flow, which can damage equipment and cause safety hazards.

- Reducing pressure: Check valves reduce pressure buildup, which can damage equipment and cause safety hazards.

- Increasing safety: Check valves increase safety by preventing reverse flow and pressure buildup.

- Reducing maintenance: Check valves reduce maintenance costs by preventing reverse flow and pressure buildup.

Conclusion

Check Valves are Essential in Preventing Reverse Flow and Pressure Buildup

In conclusion, check valves are an essential component in many industrial applications, providing numerous benefits and increasing safety. By understanding the definition, types, and applications of check valves, you can ensure the proper flow of fluids and gases in your industry. Remember, check valves are a critical component in preventing reverse flow and pressure buildup, reducing maintenance costs, and increasing safety.