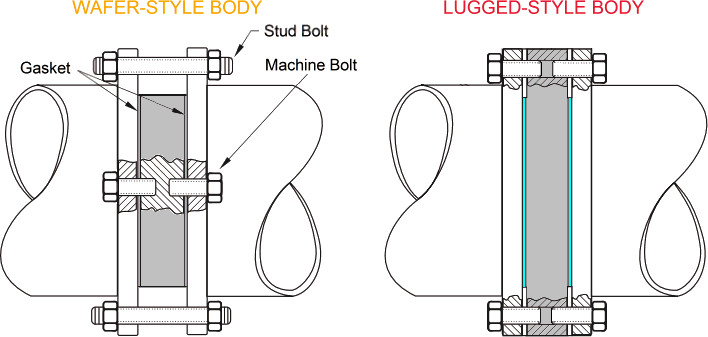

When it comes to selecting a butterfly valve for a particular application, there are several options available, including wafer and lug valves. In this article, we will provide a comprehensive comparison between wafer and lug butterfly valves, highlighting their differences, advantages, and disadvantages.

Wafer Butterfly Valves

Wafer butterfly valves are designed with a flat, round, or oval disc that is mounted on a stem. The disc has a central hole that rotates around a pivot point, allowing the valve to open and close. Wafer valves are typically used in applications where a tight seal is required, such as in chemical plants, oil refineries, and other heavy-duty industries.

Lug Butterfly Valves

Lug butterfly valves, on the other hand, have a cylindrical or rectangular body with a central hole. The valve is opened and closed by rotating the lug around a pivot point. Lug valves are commonly used in applications where a high flow rate is required, such as in water treatment plants, chemical processing, and HVAC systems.

Differences Between Wafer vs Lug Butterfly Valve

The main difference between wafer and lug butterfly valves lies in their design and functionality. Wafer valves have a flat disc that rotates around a pivot point, while lug valves have a cylindrical or rectangular body that rotates around a pivot point. This design difference affects the performance of the valve, particularly in terms of flow rate and pressure drop.

Advantages and Disadvantages of Wafer Butterfly Valves

Wafer butterfly valves have several advantages, including:

Higher pressure rating: Wafer valves can handle higher pressures than lug valves, making them suitable for high-pressure applications.

Tighter seal: The flat disc of a wafer valve provides a tighter seal than a lug valve, making it ideal for applications where leakage is not acceptable.

Lower maintenance: Wafer valves have fewer moving parts than lug valves, which reduces maintenance requirements and extends their lifespan.

However, wafer valves also have some disadvantages, including:

Lower flow rate: Wafer valves have a lower flow rate than lug valves, which can be a limitation in applications where high flow rates are required.

Limited actuation options: Wafer valves are typically actuated by a manual handle or a motor, whereas lug valves can be actuated by a variety of methods, including manual handle, motor, pneumatic, and hydraulic.