Butterfly valves are widely used in various industries, including oil and gas, chemical, and water treatment. They are known for their versatility and ability to control fluid flow with precision. We will explore the differences between these three types of valves and help you understand which one is best suited for your needs.

Double Offset Butterfly Valve

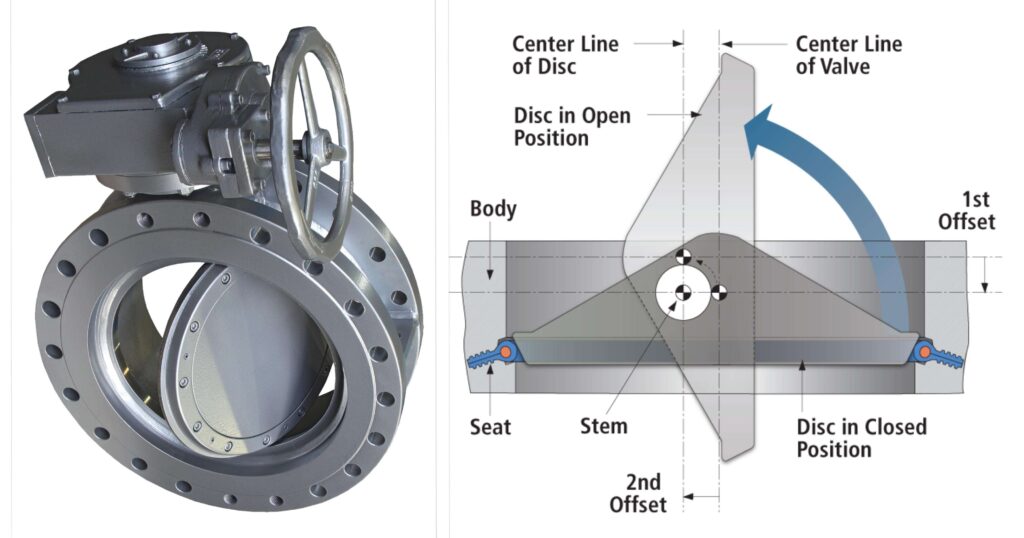

A double offset butterfly valve is a type of butterfly valve that has two offset axes. The first offset axis is located between the center of the valve and the center of the disc, while the second offset axis is located between the center of the disc and the center of the valve stem. This design allows for a greater range of motion and improved sealing performance.

The double offset design provides several benefits, including:

Improved sealing performance: The double offset design creates a tighter seal between the disc and the valve seat, reducing the risk of leakage.

Increased durability: The double offset design distributes the stress more evenly across the valve, increasing its durability and lifespan.

Better control: The double offset design allows for more precise control over fluid flow, making it ideal for applications that require precise control.

Triple Offset Butterfly Valve

A triple offset butterfly valve is a type of butterfly valve that has three offset axes. The first offset axis is located between the center of the valve and the center of the disc, while the second offset axis is located between the center of the disc and the center of the valve stem. The third offset axis is located between the center of the valve stem and the center of the valve body.

The triple offset design provides several benefits, including:

Improved sealing performance: The triple offset design creates an even tighter seal between the disc and the valve seat, reducing the risk of leakage.

Increased durability: The triple offset design distributes the stress evenly across the valve, increasing its durability and lifespan.

Better control: The triple offset design allows for even more precise control over fluid flow, making it ideal for applications that require precise control.

As shown in the table above, the sealing performance, durability, and control of the valve improve with each increase in offset. However, the choice of valve depends on the specific application and the level of performance required.

Conclusion

In conclusion, zero, double, and triple offset butterfly valves are all designed to provide precise control over fluid flow, but they differ in their level of performance. The double offset butterfly valve is ideal for applications that require improved sealing performance, increased durability, and better control. The triple offset butterfly valve is ideal for applications that require the highest level of sealing performance, durability, and control.

We hope this article has provided you with a better understanding of the differences between zero, double, and triple offset butterfly valves. Whether you’re looking for a valve for your oil and gas, chemical, or water treatment application, we have the right valve for you. Contact us today to learn more about our range of butterfly valves.