Look no further than double door check valves! These versatile valves are designed to provide reliable flow control and protection against reverse flow, making them an essential component in many industries. In this article, we will delve into the world of double door check valves, exploring their definition, types, and applications.

What is a Double Door Check Valve?

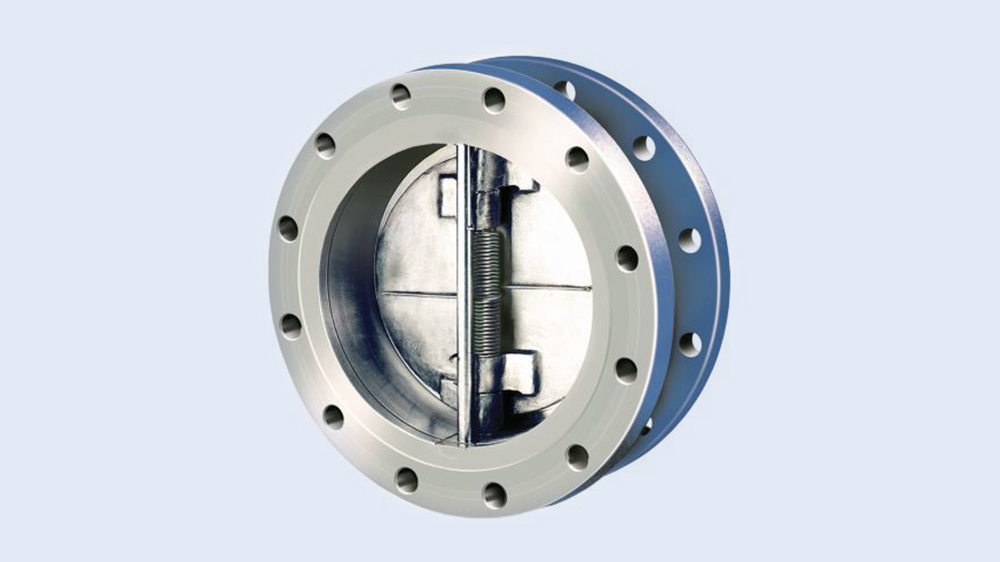

A double door check valve is a type of valve that is designed to prevent reverse flow in a pipeline. It consists of two doors or flaps that are hinged together and are positioned in the pipeline. When fluid flows through the pipeline, the doors open and close in response to the fluid flow, preventing reverse flow. Double door check valves are commonly used in applications where there is a risk of reverse flow, such as in pump stations, water treatment plants, and oil refineries.

Types of Double Door Check Valves

There are several types of double door check valves available, including:

Swing check valves: These are the most common type of double door check valve. They are designed to swing open and closed in response to fluid flow, and are available in a range of sizes and materials.

Sliding check valves: These valves are designed to slide open and closed in response to fluid flow, and are often used in applications where space is limited.

Butterfly check valves: These valves are designed to open and close in response to fluid flow, and are often used in applications where high flow rates are required.

Applications of Double Door Check Valves

Double door check valves are used in a wide range of industries and applications, including:

Water treatment: Double door check valves are used to prevent reverse flow in water treatment pipelines, ensuring that water is treated efficiently and effectively.

Oil refineries: These valves are used to prevent reverse flow in oil refinery pipelines, ensuring that oil is processed safely and efficiently.

Pump stations: Double door check valves are used to prevent reverse flow in pump stations, ensuring that water or other fluids are pumped efficiently and effectively.

Advantages of Double Door Check Valves

Double door check valves offer several advantages over other types of valves, including:

Reliable flow control: Double door check valves provide reliable flow control, ensuring that fluid flows in the correct direction.

Protection against reverse flow: These valves are designed to prevent reverse flow, which can cause damage to pipelines and equipment.

Efficient design: Double door check valves are designed to be efficient, reducing the risk of clogging and improving flow rates.

Conclusion

Double door check valves are an essential component in many industrial and commercial applications. Their ability to prevent reverse flow and provide reliable flow control makes them an indispensable tool in a wide range of industries. By understanding the definition, types, and applications of double door check valves, you can ensure that you are selecting the right valve for your specific needs. Whether you are working in water treatment, oil refineries, or pump stations, double door check valves are an essential component of any piping system.