Determining the compatibility of a 21-degree plastic collated nail gun with a specific brand of nails involves several considerations.

Here are some steps to help you assess compatibility:

- Consult Manufacturer Documentation: Check the manufacturer’s documentation for both the nail gun and the nails. The nail gun’s user manual or specifications sheet may provide information on compatible nail specifications, including nail angle, collation type, and nail length. Similarly, the nail packaging or manufacturer’s website should indicate the nail specifications.

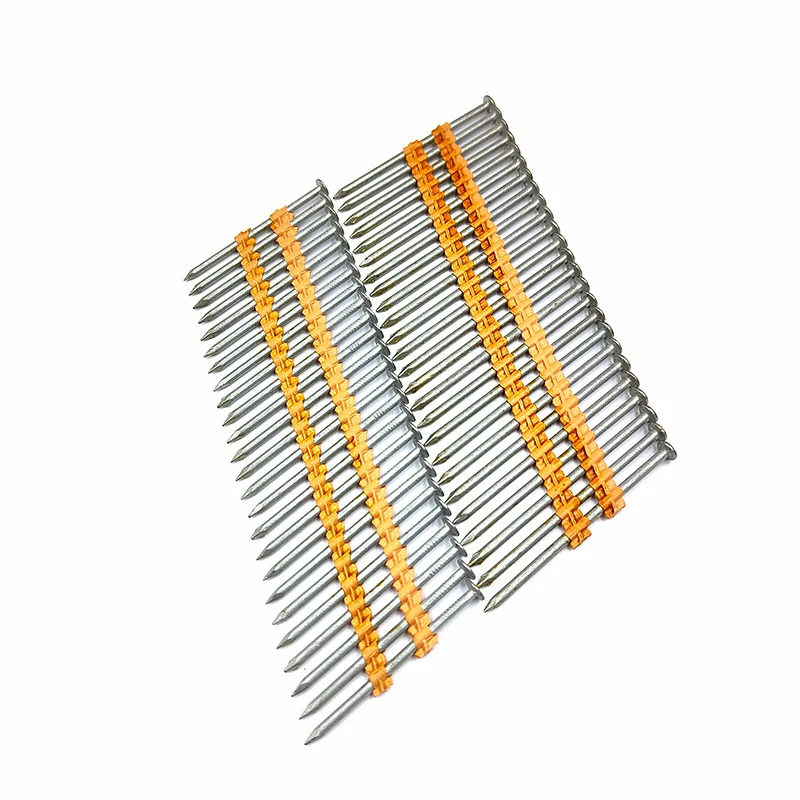

- Verify Nail Angle and Collation Type: Ensure that the nail gun is designed to accommodate 21-degree plastic collated nails. Some nail guns are specifically designed for nails with a 21-degree collation angle, while others may be compatible with different collation angles (e.g., 15-degree, 28-degree). Using nails with the wrong collation angle can cause jamming or misfeeding in the nail gun.

- Check Nail Length Compatibility: Verify that the nail gun can accommodate the length of nails you intend to use. Different nail guns have varying maximum and minimum nail length capacities. Ensure that the nails you plan to use fall within the acceptable length range for the nail gun.

- Consider Nail Shank and Head Type: Some nail guns are designed to work with specific shank types (e.g., smooth, ring, screw) and head types (e.g., clipped, full round). Check the nail gun specifications to see if it is compatible with the shank and head type of the nails you intend to use.

- Test Compatibility: If possible, test the nail gun with a small quantity of the nails you plan to use. Load the nails into the nail gun and fire a few test shots to ensure smooth feeding, proper driving, and reliable performance. If the nail gun functions without jamming or misfiring, it is likely compatible with the nails.

- Contact Manufacturer or Supplier: If you’re uncertain about compatibility, contact the manufacturer of the nail gun or the supplier of the nails for clarification. They can provide guidance on compatibility and recommend suitable nail options if necessary.

- Consider Warranty and Support: Be mindful of warranty coverage and technical support when using nails with the nail gun. Using incompatible nails may void the warranty or lead to issues that are not covered by the manufacturer’s warranty.

By following these steps and considering the compatibility factors outlined above, you can determine whether a 21-degree plastic collated nail gun is compatible with a specific brand of nails. It’s essential to ensure compatibility to achieve optimal performance and avoid potential issues during use.

How do you troubleshoot nail gun issues when using 21-degree plastic collated nails?

When troubleshooting nail gun issues while using 21-degree plastic collated nails, it’s essential to follow a systematic approach to identify and resolve the problem effectively. Here’s a step-by-step guide for troubleshooting common nail gun issues:

- Check Air Supply: Ensure that the nail gun is receiving an adequate and consistent air supply from the compressor. Check the air hose for leaks, kinks, or obstructions that may affect airflow. Verify that the compressor is set to the correct pressure recommended for the nail gun.

- Inspect Nail Loading: Examine the nail magazine to ensure that the nails are loaded correctly and securely. Make sure the nails are aligned properly and not jammed or tangled in the magazine. Remove any obstructions or debris that may impede nail feeding.

- Verify Nail Compatibility: Confirm that the nails being used are compatible with the nail gun in terms of length, diameter, collation angle, shank type, and head style. Using incorrect or incompatible nails can lead to feeding issues, jamming, or misfires.

- Check Nail Depth Adjustment: Adjust the nail depth setting on the nail gun to ensure proper nail penetration into the workpiece. If nails are not sinking fully or are overdriven, adjust the depth control knob or dial according to the material being fastened.

- Inspect Firing Mechanism: Examine the firing mechanism of the nail gun for any signs of damage, wear, or malfunction. Ensure that the trigger, safety mechanism, and contact trip are functioning correctly and engaging properly when the trigger is pulled.

- Clean and Lubricate: Clean the nail gun regularly to remove dust, debris, and residue that may accumulate in the magazine, nosepiece, or firing mechanism. Lubricate moving parts with pneumatic tool oil or lubricant as recommended by the manufacturer.

- Check for Jams: Clear any nail jams or obstructions in the nail gun by removing the magazine and accessing the nail chamber. Use a nail punch or tool to dislodge stuck nails or debris. Avoid using excessive force, which can damage the nail gun.

- Inspect Driver Blade: Check the driver blade or piston assembly for damage, wear, or deformation. clipped head nails A damaged driver blade can cause misfires or failure to drive nails properly. Replace the driver blade if necessary according to the manufacturer’s instructions.

- Test in Different Materials: Test the nail gun in different materials to determine if the issue is specific to certain types of wood, density, or thickness. Adjust the nail gun settings accordingly to achieve optimal performance in various materials.

- Consult Manufacturer’s Manual: Refer to the manufacturer’s manual or troubleshooting guide for specific instructions on diagnosing and resolving nail gun issues. Follow any recommended procedures or maintenance steps provided by the manufacturer.

- Contact Customer Support: If troubleshooting steps do not resolve the issue, contact the manufacturer’s customer support or technical service for assistance. Provide details about the problem, nail gun model, and any troubleshooting steps you have already taken.

By following these troubleshooting steps, you can identify and resolve nail gun issues effectively, ensuring reliable performance and safe operation when using 21-degree plastic collated nails. It’s important to prioritize safety and follow manufacturer recommendations for maintenance and repairs.