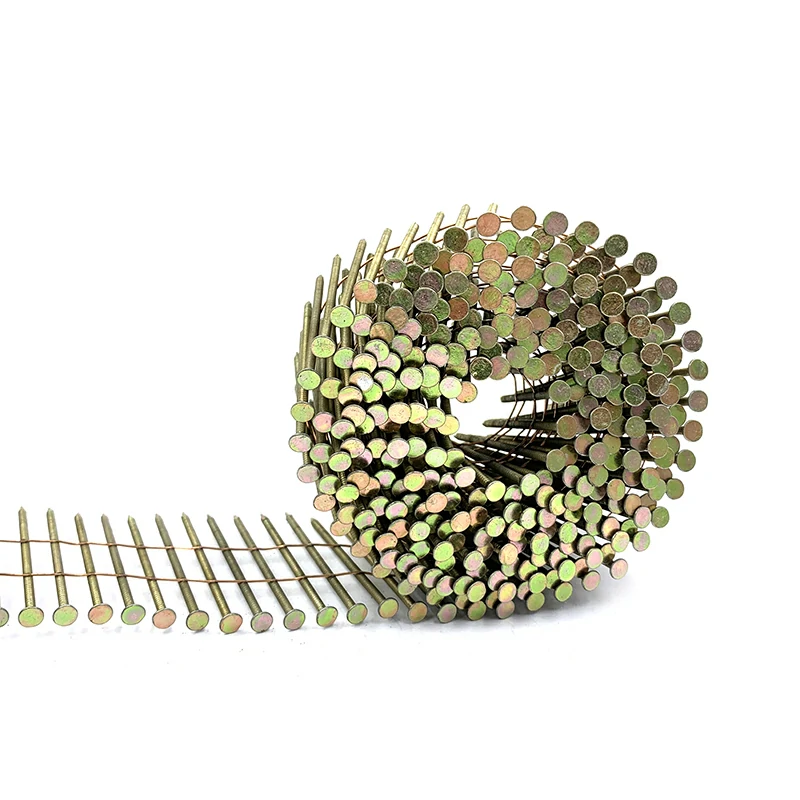

The performance of 25mm coil nails, or any type of fasteners, in regions with extreme weather conditions can vary depending on several factors, including the materials used in the nails, the specific application, and the severity and duration of the weather conditions.

Here are some considerations regarding the performance of 25mm coil nails in regions with extreme weather conditions:

- Material composition: 25mm coil nails are typically made from hardened steel, which provides strength and durability. Steel can withstand moderately high temperatures without significant degradation. However, prolonged exposure to extreme heat or cold may affect the performance of the nails.

- Galvanized coating: Many 25mm coil nails are coated with a layer of zinc (galvanized) to provide corrosion resistance. Galvanized nails are more resistant to rust and corrosion, making them suitable for use in regions with high humidity, rainfall, or saltwater exposure.

- Resistance to moisture: Moisture is a common factor in extreme weather conditions, and it can lead to rust and corrosion of metal fasteners. Properly galvanized 25mm coil nails are more resistant to moisture, which helps maintain their strength and integrity in wet or humid environments.

- Resistance to temperature fluctuations: Extreme temperature fluctuations, 25mm coil nails such as those experienced in regions with hot summers and cold winters, can affect the performance of fasteners. Steel expands and contracts with changes in temperature, which may cause nails to loosen or weaken over time.

- Wind resistance: In regions prone to high winds or storms, fasteners are subjected to significant forces that can cause them to loosen or pull out of the substrate. Proper installation techniques, such as using the correct size and type of nails and ensuring sufficient penetration into the substrate, can help improve the wind resistance of 25mm coil nails.

- UV resistance: Exposure to ultraviolet (UV) radiation from sunlight can degrade certain materials over time. While steel is not affected by UV radiation, any coatings or finishes applied to the nails may deteriorate when exposed to prolonged sunlight.

- Maintenance and inspection: Regular inspection and maintenance of fasteners installed in regions with extreme weather conditions are essential to identify any signs of degradation or corrosion early on. This may involve periodic visual inspections, checking for signs of rust or deterioration, and replacing any nails that show signs of damage.

In summary, while 25mm coil nails are generally durable and capable of withstanding moderate weather conditions, their performance in regions with extreme weather may be influenced by various factors. It’s essential to consider the specific application, material composition, installation techniques, and maintenance practices to ensure the longevity and reliability of coil nails in such conditions.